Synthesis and preparation of silicon carbide

Synthesis and preparation of silicon carbide ceramics

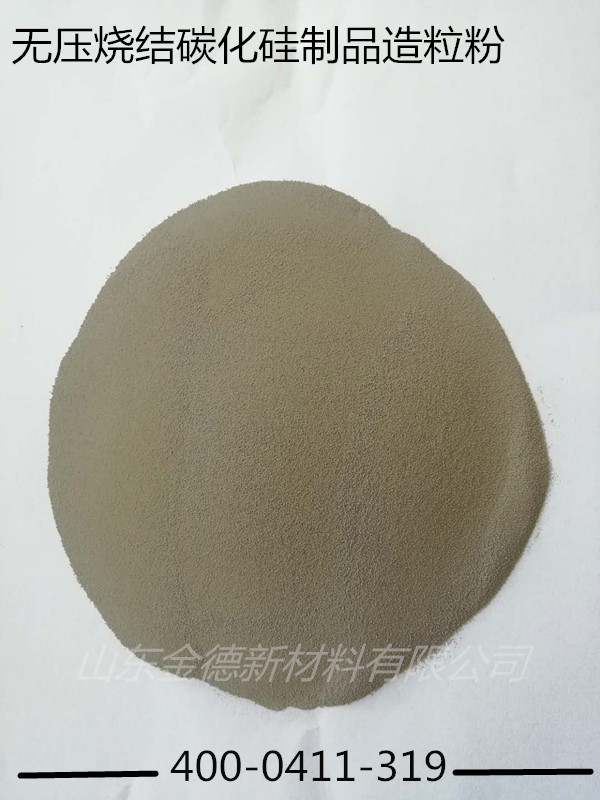

Due to the characteristics of covalent bonding, the diffusion rate of SiC is rather low. Even in the high temperature of 2100oC, the self diffusion coefficient of C and Si is only 1.5 * 10-10 and 2.5 * 10-13 cm2/s. So It is difficult to take the normal pressure sintering process of the simple compound used in the ionic bond material to make the high density material, which must be made by some special technological means or by the second phase material. SiC is hard to sinter. The ratio of grain boundary energy and surface energy is very high, and it is not easy to get enough energy to form the grain boundary. The diffusion rate of SiC is very low, and the oxide film on the surface of the sintering process also has a diffusion barrier. Therefore, silicon carbide need to use additives or pressure to get a dense material. This part uses Al-B-C as sintering aids.

Selective segregation of boron(B) at the SiC grain boundary decreases the grain boundary energy and improves the sintering driving force, but excess B can cause the abnormal growth of SiC grains. The addition of C (carbon) can reduce the SiO2 film which is hindered by sintering, and improve the surface free energy. But too much carbon will cause the weight lose and density decreased. Aluminum (Al) has the effect of inhibiting the growth of grain and enhancing the sintering aids of boron. But excess of Al will make the parts of the high temperature strength decreased. Therefore, it is necessary to determine the amount of Al, B, and C by experiment. At present, the main methods of producing SiC ceramics are non pressure sintering, hot pressing sintering, HIP sintering, reaction sintering and so on.

相关资讯

最新产品

同类文章排行

- 工业领域大规模设备更新来了!

- 什么是微通道反应器

- 一图看懂新质生产力

- 山东省应急管理厅通知:年底前,硝化工艺企业全部应用微通道、管式反应器等先进技术装备!

- 一图读懂两会报告

- 【2024山东两会】一图读懂山东省政府工作报告

- 浅谈碳化硅

- 什么是微化工技术?

- 从实验研发到工业化应用中设备放大应注意的问题

- 碳化硅陶瓷加热板在热弯机方面的应用前景

最新资讯文章

您的浏览历史